Slump Test

INTRODUCTION

The slump test indicates the behaviour of a compacted concrete cone under the action of gravitational forces. The slump test is a practical means of measuring the workability i.e., consistency of concrete, where the nominal maximum size of the aggregate does not exceed 38mm. Changes in the value of slump obtained during a job may indicate changes in materials, in the water content or in the proportions of the mix, so it is useful in controlling the quality of the concrete produced.

The slump test is the most commonly used method for evaluating the flow properties of fresh concrete; it provides a measure of workability. The slump can be determined using this test by measuring the drop from the top of the slumped fresh concrete. The prediction of concrete flowability is critical for on-site construction in the task of concrete mixture design. As the complexity of concrete construction increases, material engineers face increasing pressure to achieve high workability while maintaining the mechanical properties necessary to meet design specifications.

In order to calculate dry volume of material mix, we multiply the wet volume of concrete by 1.52 to 1.54. As water is added in dry material mix to obtain wet concrete and then placed in shuttering particles slides to readjust in pores and voids reducing the volume of it. Coarse aggregate has a void ratio compressibility of 32 to 33 percent, whereas fine aggregate has a void ratio compressibility of 20 percent. Assuming that the cement particles being very fine get adjusted in compressed voids, the total volume of dry material (having 0.33 +0.20=0.53 voids) has nearly 52 to 54 % more volume than when in wet state. Hence, the volume of dry material for concrete is calculated by multiplying wet concrete quantity by 1.54. Here the density of cement is measured in Kg/m3 (kilograms/cubic meter). It is the ratio of mass to volume, so the density of cement in kg/m3 is 1500.

The application of slump test is:

Used to ensure uniformity for different batches of similar concrete under field conditions and to ascertain the effects of plasticizers on their introduction.

This test is very useful on site as a check on the day-to-day or hour- to-hour variation in the materials being fed into the mixer.

Too high or too low a slump gives immediate warning and enables the mixer operator to remedy the situation.

Limitations of the slump test:

The slump test is suitable for slumps of medium to high workability, slump in the range of 5 – 260mm. The test fails to determine the difference in workability in stiff mixes which have zero slump, or for wet mixes that give a collapse slump. It is limited to concrete formed of aggregates of less than 38mm.

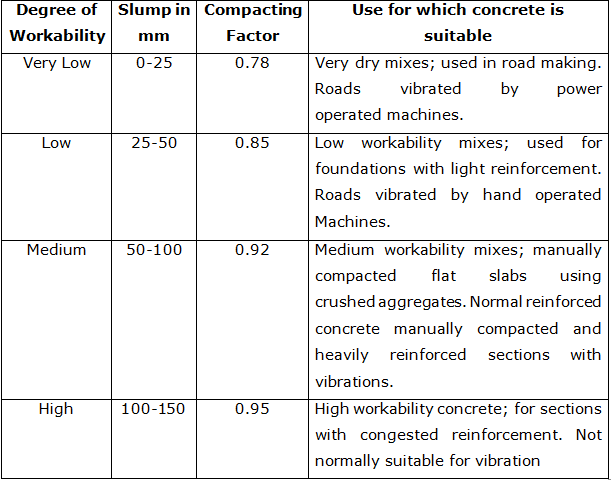

Recommended Values of Slump for Different Applications

( Source: IS_456_2000 )

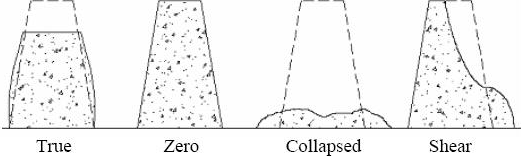

Different Shapes of Slump

( Source: http://www.studycivil.com/slumptestfortheworkibilityofconcrete/ )

Relevant Indian Standard for Slump Test:

- IS 7320 -1974 : Methods of Sampling and Analysis of Concrete, Reaffirmed 2004.